Capabilities

At Ultra-Met Carbide Technologies, draw on 60 years of experience in manufacturing tungsten carbide tools, wear parts, hardware, and components. From RTP (ready to press) powder metal material development to powder metal manufacturing and machining, we use advanced molding and sintering technology to create the part features, shapes, or geometries our customers require.

As a leading independent manufacturer of custom-molded tungsten carbide products, we proudly maintain state-of-the-art machining centers for custom moldmaking, CNC presses, sintering furnaces, and finishing equipment. Recently, we have also added a 200-ton press to improve our carbide manufacturing capabilities. We serve a variety of industries that rely on durable cutting tools, hardware, and other components, including:

Aerospace

Automotive

Manufacturing

Metalworking

Mining

Oil and Gas

Woodworking

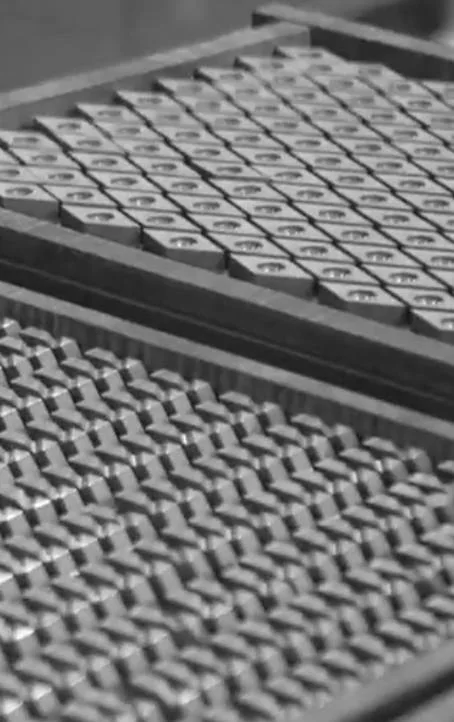

Ultra-Met Carbide Technologies offers end-to-end powder metal manufacturing services to produce carbide preforms, mining bits CNC PRessing for Compaction Section, woodworking inserts, wear parts, solid rods, and other custom shapes. Our capabilities and equipment allow us to create products in a broad range of densities and hardnesses to meet customer specifications.

What’s more, our various preform products allow for easy removal of large portions of carbide while components are in their green state, leaving a trace amount of grind stock. This makes for a faster finishing process that puts less wear on grinding equipment and saves our customers time and money.

For custom orders, our experienced team offers unparalleled support and guidance through every step of the manufacturing process. We can assist with material selection, design and engineering, and more to optimize your components. Keep reading to learn more about our process and our capabilities.

CNC Pressing for Compaction

We use the most advanced CNC presses on the market and can make many different shapes with intricate features. Our CNC presses range from 16 tons to our newest 200 ton press. This new press can make parts over 0 in. long and 4 in. tall. We also utilize our ISO Press for very large carbide components. With this machine we can press and sinter carbide over 15 in. long.

At Ultra-Met Carbide Technologies, we use CNC presses to compact dies that have been filled with powder metal material. After the material is blended to make the appropriate formulation of tungsten carbide, cobalt, nickel, binders, or lubricants, it is prepared for molding and placed in a die.

The press applies steady, high pressure to the die from above and below, compacting the powder into a solid object that holds its form when removed from the die. Compaction creates what is called a green compact, or a component in its “green state.” At this stage it is in its final shape and is durable enough to be handled or machined; however, the metal particles will not be bonded and the component will not reach its final strength and density until it is sintered.

Sintering for Strength and Density

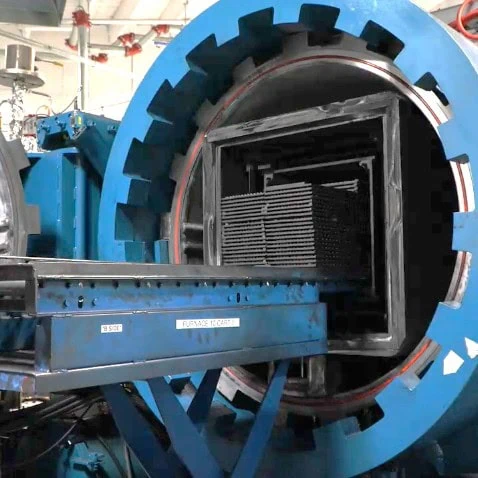

Once the material is compacted it is ready for sintering. In this process, the green compacts are placed into a sintering furnace under specific temperature and atmospheric conditions for a predetermined amount of time. The compacts are heated to a temperature below their melting point, which bonds the particles without melting them, forming a durable, dense structure. This process is highly efficient because multiple components can often be sintered at the same time.

Different methods are available, depending on the materials, part characteristics, and application details. We use these sintering methods:

- Hot Isostatic Pressing (HIP) Sintering. Components are placed in a pressurized vessel with inert gas, such as argon. The temperature is raised at the same time. This process increases the density of the finished part.

A vacuum sinter process that involves a post-HIP. The carbide is the first vacuum sinter, and at the end of the process, the vacuum gets replaced by pressurized argon gas from various atmospheres. This process creates a sealed envelope around the carbide consisting of molten binder metals.

- Vacuum Sintering. Here the heating process takes place inside a vacuum, which eliminates any atmospheric gases that could cause oxidation or other contamination of the metal particles so they can form secure bonds.

A vacuum or partial argon environment heats the green carbide.

Carbide Powder Metal Manufacturing with Custom Dies

All of our presses use the latest die technology to press carbide parts with high precision. We design and manufacture custom dies in-house, based on 3D modeling and simulations that allow us to develop dies that hold tight tolerances with minimal flashing. These dies, in conjunction with our CNC controlled presses, allow for a superior finished part.

We use these three types of dies in our powder metal manufacturing processes:

- Standard. These consist of a single die cavity that forms the outer shape of the part, upper and lower punches that further compact the material, and sometimes an inner rod to form internal features.

- Split Cavity. These consist of two pieces that are clamped together to form a single die cavity during compaction. They are well-suited to intricate, asymmetrical, or multi-angle part shapes as well as high-volume production. They also make it easier to remove the compact from the mold since the halves can be taken apart.

- Multiple-Out. These are multi-cavity molds that can create more than one part in each pressing cycle. It is important to ensure complete filling and compaction when using these dies.

From the initial concept to completion, we optimize every detail for precision, performance, and manufacturability, offering the best results.

Comprehensive Carbide PM Manufacturing Services

At Ultra-Met we have the technical knowledge and experience to manufacture nearly any shape or type of tungsten carbide powder metal component our customers can imagine. Our products, services, and capabilities are a complete solution for manufactured parts and components, including:

- Custom die design and manufacturing.

- Extensive selection of blanks, including preforms, threaded, milled, drilling, grooved, turned, and rectangles.

- Catalog of drill bits, woodworking inserts, round preforms, wear parts, and more.

- In-stock solid carbide rod selection with same-day delivery usually available.

- Private label program of finished and semi-finished products.

- Prototyping with design and engineering support.

- Custom manufacturing to your requirements, including pressed on angle capability, complex geometries and topographies, and press-to-size capabilities.

- Variety of RTP powder materials for sale.

Our high-quality products and custom capabilities give customers in the metal-cutting and tool-making markets exceptional dimensional precision and carbide materials that excel in demanding machining applications. We are also ISO9001:2015 registered for quality.

Contact Ultra-Met Carbide Technologies

Since our earliest days in 1965, Ultra-Met Carbide Technologies has been a leader in tungsten carbide powder metal manufacturing technology. With engineering, metallurgical, and material science expertise, we can reliably deliver standard and custom components for applications in a range of industries.

Contact Ultra-Met Carbide Technologies, the premier choice for high-quality press-to-size inserts, high-performance toolmaker blanks, and custom-molded carbide products. If you’re ready to order or discuss your application, request a quote today!